6-20 个字符(仅限字母加数字)

密码不一致

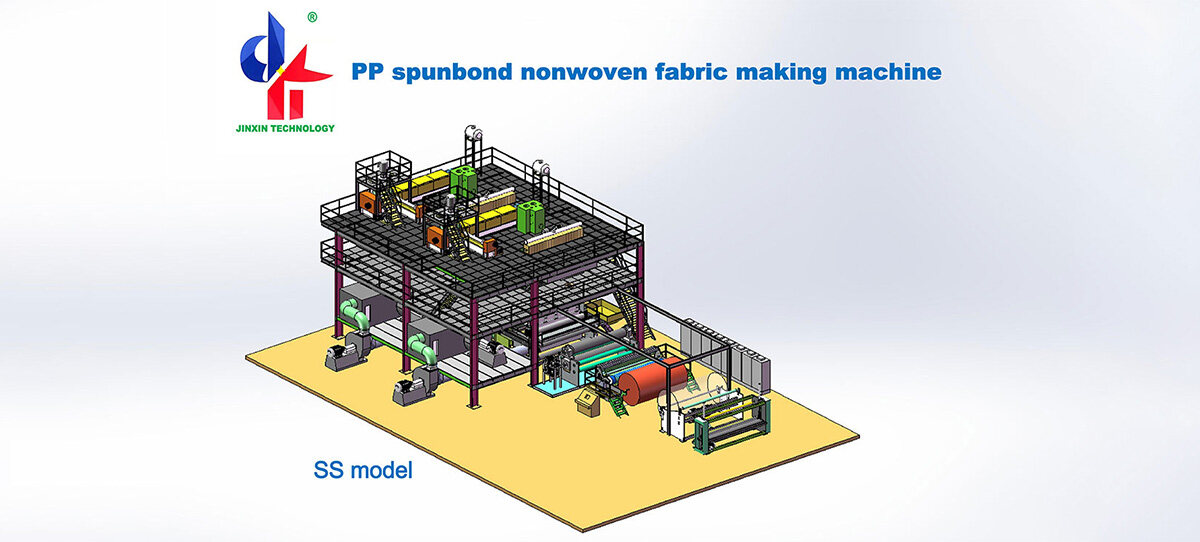

1600mm SS non-woven fabric machine

The equipment made of non-woven fabric transcends the conventional textile principle. It is created by orienting or randomly arranging the short textile fibres or filaments to create a fibre web structure, and then fortifying it using mechanical, chemical, or thermal bonding techniques. Without spinning or weaving, the fibre web is created, making it light, soft, elastic, corrosion-resistant, and washable.

| Model | JX-SS |

|---|---|

| Product Width | 1600mm |

| Equipment Size | 30*12*12m |

| Mechanical Speed | 300m/min |

| Gram Weight | 10-200g/m2 |

| Daily Output | 7-12T/Day |

| Transformer Capacity | ≈400KVA |

| Power Consumption | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The non-woven fabric equipment breaks through the traditional textile principle. It is formed by orienting or randomly arranging the textile short fibers or filaments to form a fiber web structure, and then strengthening it by thermal bonding, mechanical or chemical methods. The fiber web is formed without spinning and weaving, so it is light, soft, elastic, corrosion-resistant, and washable.

What are the performance characteristics of professional non-woven equipment?

1.Professional non-woven equipment has been optimized in structure, which is more compact. The non-woven fabric equipment can integrate all the tools needed for non-woven fabric processing into one piece of equipment to achieve unified coordination. Therefore, professional non-woven fabric equipment is often small in size.

2.Stable operation is an important prerequisite for the output and quality of non-woven fabrics. The non-woven fabric equipment that can continuously maintain stable operation can unify the quality of non-woven fabric products, achieve a better product price effect, and promote the production of non-woven fabrics.

3.The non-woven fabric equipment adopts the aluminum profile frame as the main body. The structure is solid and durable, is not easy to rust, has a long service life, and is relatively convenient for installation and maintenance. Therefore, the experience of using non-woven fabric equipment is quite good.

4.The automatic control mode of non-woven fabric equipment can realize rapid batch production of non-woven fabric. Therefore, it can improve the output of non-woven fabric products, reduce labor costs, and bring higher benefits to the enterprise.

FAQ

1.Q: How long will your engineer reach our factory?

A: Within one week after everything is ready (machine arrival at your factory, nonwoven material, power source, air compressor, etc.Prepared)

2.Q: Does your engineer understand English?

A: Our engineers understand a little English. All our engineers have more than five years of machine installation experience.

3.Q: What should we charge for your engineer?

A: You should charge for the cost of our engineer’s air tickets, hotel, food, and also their salary of 800CNY one day per person.

4.Q: How many days it will take for the installation?

A: It will take around 45 days, depending on the machine type.

5.Q: How do we solve the machine problem after your engineer leaves?

A: Generally speaking, there will be no problem after finishing the installation. In case you have any problem, you can contact us.